ATEX CERTIFIED SOLUTIONS

Illuminate with Confidence: Elevating Lighting Standards with ATEX Certified Solutions by LEDFlex – Where Safety and Brilliance Unite.

-

Explosion-Proof

Design -

ATEX

Certification -

IP

Rated -

Robust

Construction -

Temperature

Control -

Corrosion

Resistance -

Zone

Classification

LEDFlex now offers a range of linear lighting solutions that are Atex compliant, making them an ideal solution for hazardous, explosive environments. Explosive atmospheres can be caused by flammable gases, vapours or combustible dusts which can cause serious injuries as well as significant damage to surroundings areas.

The EU directives distinguish between two different types of explosive atmospheres: gas and dust in high pressure environments. Atex certified products undergo rigorous testing as outlined by the EU directives to ensure that they are intrinsically safe and that the products can be used safely in specific environments without causing a spark or reaching a high temperature which could easily ignite an explosive atmosphere.

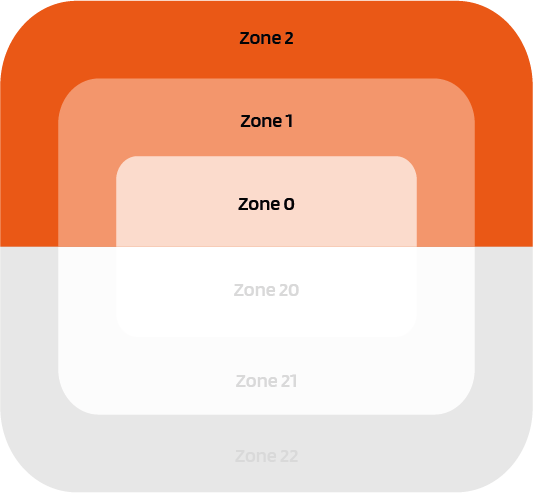

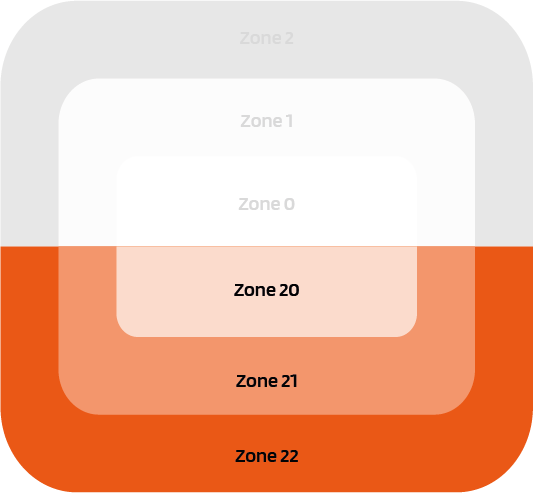

Explosive Gas Atmosphere

-

Zone 0

An explosive atmosphere consisting of a mixture with air and dangerous substances in the form of gas, vapour or mist is present continuously. -

Zone 1

An explosive atmosphere consisting of a mixture with air and dangerous substances in the form of gas, vapour or mist is occasionally present during normal working practices. -

Zone 2

An explosive atmosphere consisting of a mixture with air and dangerous substances in the form of gas, vapour or mist is not likely to occur in normal operation or is present only for short periods of time.

Explosive Dust Atmosphere

-

Zone 20

An explosive atmosphere in the form of a cloud of combustible dust in the air is present continuously. -

Zone 21

An explosive atmosphere in the form of a cloud of combustible dust in the air is likely to occur during normal working practices. -

Zone 22

An explosive atmosphere in the form of a cloud of combustible dust in the air is not likely to occur in normal operation or is present only for short periods of time.

Application for Atex Solutions

LEDFlex, with our new explosive proof lighting solutions, is committed to assuring safety whilst offering a premium finish for any lighting design concept. Our flexible linear lighting easily copes with a range of complex environments when combined with purpose-built accessories. The explosion proof luminaires distribute consistent and continuous light, ensuring safe and well-lit spaces built for indoor and outdoor hazardous environments across various industries.

Mining

Mines and factories are commonly known to have hazardous environments due to the volume of high pressure labour and use of heavy duty equipment.

Oil & Gas

Oil and gas industries face the risk of fire and explosion due to ignition of flammable gases such as hydrogen sulphide which can be released from wells, trucks, production equipment.

Transport

Underground tubes, railway trains, airplanes all pose potential risks on account of how they are designed as compact spaces with a confined amount of airflow.

Marine

From cruise ships to yachts, watercrafts retain a large amount of flammable gases and fuel emissions that have the potential to create temperamental conditions onboard.

Key Features of ATEX Lighting

ATEX lighting fixtures are designed with materials and construction methods that minimize the risk of generating sparks, heat, or other forms of ignition. This helps prevent the ignition of flammable substances in the surrounding atmosphere.

ATEX lighting fixtures must undergo rigorous testing and certification by authorized bodies to ensure they meet the required safety standards. The certification process involves assessing the lighting's suitability for different hazardous zones and classifications.

Zones and Classification**: Hazardous areas are classified into zones based on the likelihood and duration of the presence of explosive atmospheres. ATEX lighting fixtures are categorized to match the specific zone they are intended for. Zone 0 and Zone 20 are the most hazardous, while Zone 2 and Zone 22 are less hazardous.

ATEX lighting fixtures can incorporate different protection methods, such as:

Explosion-Proof (Ex d)

These fixtures are designed to contain any explosion that might occur inside the fixture, preventing it from spreading to the surrounding atmosphere.

Increased Safety (Ex e)

These fixtures are constructed to minimize the risk of sparks, and they have enhanced protection against dust and moisture ingress.

Intrinsically Safe (Ex i)

These fixtures use low electrical energy that cannot ignite a hazardous atmosphere, even if there's a fault or short circuit.

Dust Ignition Protection (Ex tD)

This protection method is specifically designed for environments with combustible dust.

ATEX lighting fixtures are built to withstand harsh conditions, such as corrosive chemicals, extreme temperatures, and physical impact.

Regular inspection and maintenance of ATEX lighting fixtures are essential to ensure they continue to function safely and effectively in hazardous environments.

It's crucial to note that ATEX regulations and standards may vary depending on the region and industry. Therefore, individuals and businesses that operate in potentially explosive atmospheres should consult relevant authorities and experts to ensure they select and install appropriate ATEX lighting solutions for their specific needs.

Frequently asked Questions

01 What is ATEX linear lighting?

ATEX linear lighting refers to lighting fixtures designed and certified to be used in potentially explosive atmospheres, where the presence of flammable gases, vapours, or dust could create an explosive environment. These fixtures are built to prevent sparks, ignition, and overheating, ensuring safety in hazardous areas.

02 Where are ATEX linear lighting fixtures typically used?

ATEX linear lighting fixtures are commonly used in industries such as oil and gas, petrochemical, chemical manufacturing, mining, pharmaceuticals, and food processing, where explosive or flammable materials may be present.

03 What are the key advantages of using ATEX linear lighting?

The main advantages of ATEX linear lighting include enhanced safety, compliance with regulatory standards, durability in harsh environments, and energy efficiency. These fixtures minimise the risk of ignition and explosion while providing adequate illumination.

04 How is ATEX linear lighting different from regular linear lighting?

ATEX linear lighting is specifically designed and certified for use in hazardous areas. It undergoes stringent testing to ensure it meets ATEX directives and can safely operate in environments with potentially explosive atmospheres. Regular linear lighting is not suitable for such environments.

05 What ATEX certifications should I look for when choosing ATEX linear lighting?

When selecting ATEX linear lighting fixtures, you should look for certifications from recognised bodies, such as ATEX Directive 2014/34/EU for Europe or equivalent certifications in other regions, like IECEx. The specific certification will depend on your location and application.

06 What are the different ATEX zones, and how do they affect my choice of ATEX linear lighting?

ATEX zones are classified based on the likelihood and duration of the presence of explosive atmospheres. Zones include Zone 0, Zone 1, Zone 2 for gases, and Zone 20, Zone 21, Zone 22 for dust. The choice of ATEX linear lighting should align with the zone classification of your hazardous area.

07 Can ATEX linear lighting fixtures be installed in wet or corrosive environments?

Some ATEX linear lighting fixtures come with high IP ratings (Ingress Protection) and corrosion-resistant materials, making them suitable for wet and corrosive environments.

It's important to choose fixtures that match the environmental conditions of your installation.

08 Can ATEX linear lighting be used in retrofits or new installations?

ATEX linear lighting fixtures are suitable for both retrofitting existing hazardous environments and installing in new construction. However, it's crucial to ensure that the chosen fixtures match the specific requirements of your application and comply with local regulations.

Contact with us

It's very easy to get in touch with us. Just use the contact form or pay us a visit for a coffee at the office. Dynamically innovate competitive technology after an expanded array of leadership.